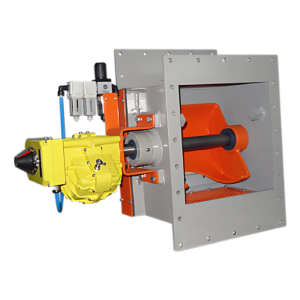

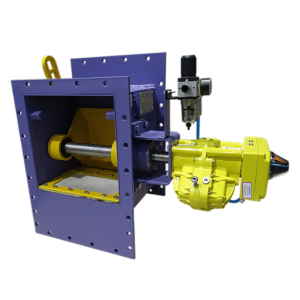

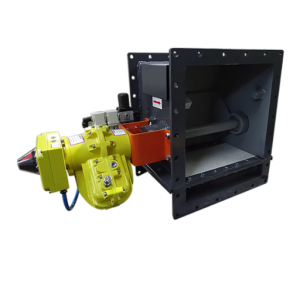

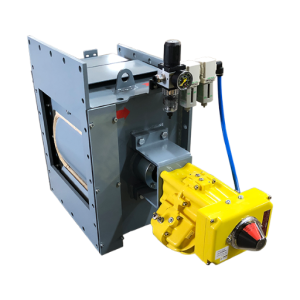

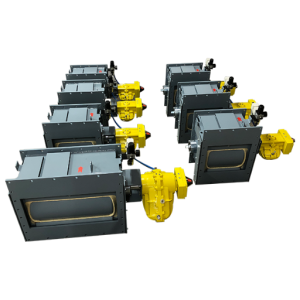

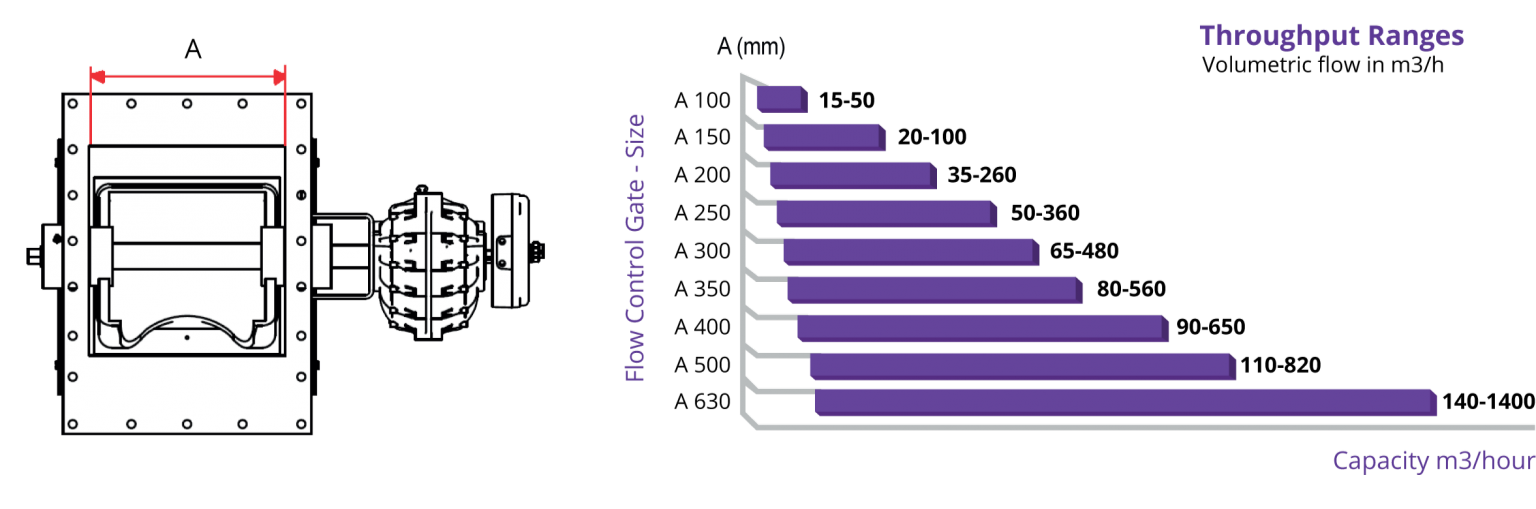

Flow control gate delivers all the benefits and functionality expected from globally recognized flow control technologies. Its various configurations—equipped with different actuators—share a common advantage: exceptional precision in regulating the flow of fine, powdered bulk materials, ensuring consistent and repeatable results.

These flow control gates are designed for minimal maintenance needs. Still, even highly durable equipment can experience wear over time, especially in demanding industrial environments.

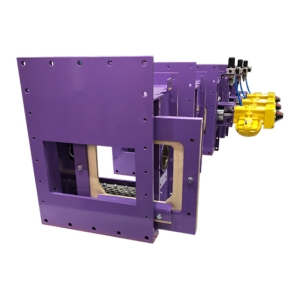

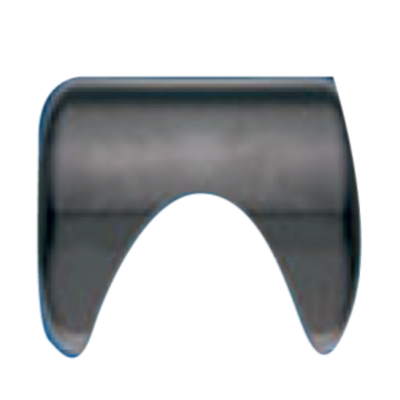

Unlike other designs that may require the complete disassembly of the unit for servicing, this flow control gate offers a more efficient solution. Its smart construction allows for maintenance to be performed without removing the entire gate. By simply detaching a side cover, the roller becomes accessible and can be removed with ease. This provides direct access to the seal, which can be replaced if necessary. Reassembly is straightforward and performed in reverse order, minimizing downtime and labor.

High-Precision Flow Control Gate by Mor Endüstri Ltd.

Trusted by professionals in industries where precision matters, Mor Endüstri Ltd.’s Flow Control Gate offers a reliable solution for efficient bulk material handling.