Improving Accuracy with Flow Control Gates

Flow control is critical in many industrial processes, particularly where materials need to be transported or dispensed with precision. One of the most reliable solutions for achieving controlled material flow is the Flow Control Gate. Serving as a proportional valve, a Flow Control Gate ensures that material moves through pipelines or channels in a precisely regulated manner, helping industries maintain quality, efficiency, and safety.

Understanding Flow Control Gates

Understanding Flow Control Gates

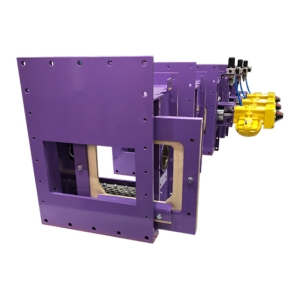

A Flow Control Gate is engineered to provide linear and proportional control over material flow. Unlike traditional on/off valves, which merely allow or block flow, a flow control gate can adjust its aperture gradually, ensuring that the material passes at the desired rate. This proportional adjustment makes it suitable for applications requiring high precision, such as bulk material handling, food processing, chemical transport, and pharmaceutical production.

The design of a Flow Control Gate varies depending on the drive type, roller type, application, and required capacity. These gates can be pneumatically driven, motor-driven, or manually adjustable, providing versatility across industries. Mor Endustri Ltd, a recognized manufacturer in Turkey, combines decades of gate production expertise with premium components to deliver high-accuracy Flow Control Gates tailored to specific operational needs.

High-Precision Pneumatic Gates

For pneumatic applications, the choice of actuator is critical to achieving precise flow control. Mor Endustri collaborates with Kinetrol UK, a leading brand for pneumatic actuators and positioners, ensuring reliability and durability. Kinetrol actuators provide accurate positioning within 0°-90°, allowing the flow control gate to regulate material with high fidelity. This combination of Mor Endustri’s gate design and Kinetrol’s actuators results in a product that offers long-term performance and minimal maintenance requirements.

Key Features of Flow Control Gates

Key Features of Flow Control Gates

- Position Control via Feedback Signal: Feedback systems enable the gate to adjust automatically based on real-time flow requirements, reducing manual intervention and ensuring consistent operation.

- Reliable Dust-Tight Shut-Off: Industrial materials, especially powders and granules, can generate dust that interferes with system performance. Flow Control Gates feature dust-tight seals, preventing contamination and maintaining a clean environment.

- Linear Control Aperture: The gate provides a linear relationship between actuator movement and flow rate, making flow adjustments predictable and precise.

- 2×3 Wire Microswitches for SPDT: These switches enhance monitoring and automation by providing position status signals for control systems.

- Exchangeable Cassette-Type Sealing: The sealing system is designed for easy replacement and maintenance, minimizing downtime in industrial processes.

- Steel Construction Housing and Roller: Robust construction ensures durability, especially in abrasive or high-pressure environments.

- Manual Adjustment Lever: For operations requiring manual override, the lever allows operators to adjust flow without relying on power or pneumatic input.

- Normally Closed Feature: In case of power or air failure, the gate defaults to a closed position, preventing unintentional material flow and ensuring safety.

Customization and Versatility

Mor Endustri manufactures Flow Control Gates to meet specific customer requirements. Depending on the application, the gates can be designed with pneumatic cylinders or geared motors as drives. This flexibility allows industries to choose the best actuator type for their operational environment, whether it’s high-speed filling, bulk material discharge, or precise dosing.

Flow Control Gates are also scalable in size and capacity. From small units handling light materials to large gates controlling bulk solids, Mor Endustri can deliver a solution tailored to the throughput and space constraints of each facility.

Maintenance and Longevity

One of the most important considerations in industrial equipment is maintenance. Flow Control Gates from Mor Endustri are designed with exchangeable cassette-type seals, meaning that routine maintenance does not require complete disassembly. Combined with the long-lasting Kinetrol actuators, these gates provide reliable performance over many years, reducing operational costs and improving uptime.

Applications Across Industries

Flow Control Gates find applications across a wide range of industries:

- Bulk Material Handling: Controlling the flow of grains, powders, or pellets in storage and transport systems.

- Chemical and Pharmaceutical Industries: Ensuring precise dosing of ingredients and preventing cross-contamination.

- Food Processing: Managing the flow of dry ingredients, powders, or granular products.

- Energy and Utilities: Controlling coal, ash, or other bulk materials in energy production processes.

By providing precise flow control, these gates help facilities optimize efficiency, reduce waste, and maintain strict quality standards.

Advantages of Using Flow Control Gates

Using a Flow Control Gate over other types of valves offers several benefits:

- High Accuracy: Proportional flow control ensures materials are delivered at exactly the required rate.

- Durability: Robust construction with steel housing and rollers handles abrasive and high-pressure materials.

- Low Maintenance: Exchangeable seals and high-quality actuators minimize downtime and service needs.

- Safety: Normally closed design prevents accidental material flow during power or air failure.

- Automation Compatibility: Feedback systems and microswitches allow integration into automated control systems for precision management.

FAQ – Frequently Asked Questions

Q1: What materials can Flow Control Gates handle?

A1: Flow Control Gates are suitable for a wide range of materials, including powders, granules, pellets, and bulk solids. Specific material compatibility may depend on the seal type and housing design.

Q2: Can Flow Control Gates be automated?

A2: Yes. Gates can be equipped with feedback signals and microswitches for SPDT, allowing integration into automated process control systems.

Q3: What happens if there is a power or air failure?

A3: The gates are designed to be “normally closed,” meaning they automatically shut off flow to prevent spillage or safety hazards.

Q4: How easy is it to maintain the gate?

A4: Maintenance is simple due to exchangeable cassette-type seals, which allow quick replacement without full disassembly.

Q5: Can the gate be manually adjusted?

A5: Yes. A lever allows manual adjustment in case manual operation is necessary or during maintenance.

Conclusion

Flow Control Gates are essential components for industries requiring precise and reliable material flow management. By combining linear control, high-quality actuators, and robust construction, Mor Endustri provides gates that enhance operational accuracy, safety, and efficiency. Whether pneumatic, motor-driven, or manually operated, these gates are a versatile solution for controlling materials in modern industrial applications. With their focus on longevity, easy maintenance, and automation compatibility, Flow Control Gates represent a critical investment for facilities aiming to optimize their production processes.