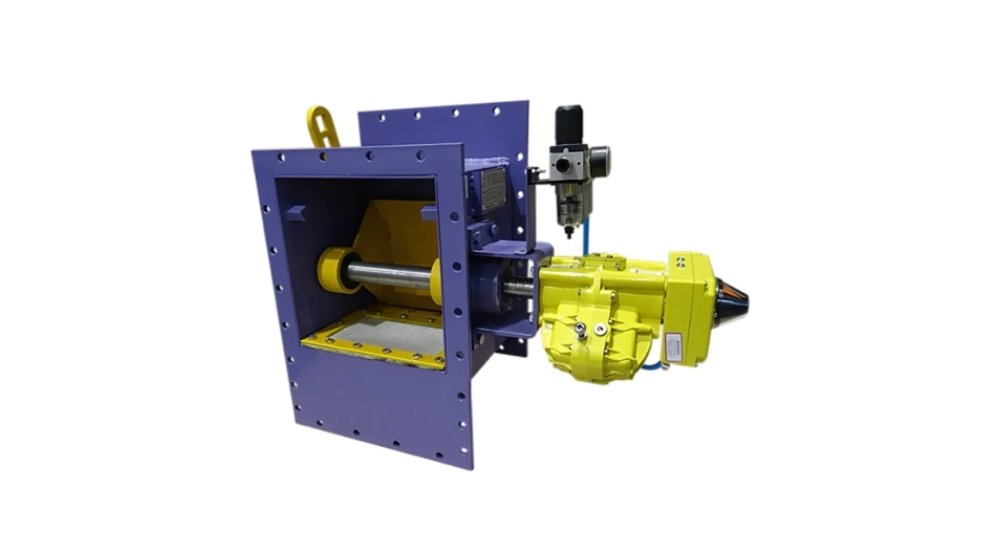

How to Select the Right Flow Control Gate for Bulk Material Handling

Selecting the right flow control gate for bulk material handling is a pivotal decision that can significantly impact the operational efficiency and safety of industrial processes. These gates are essential components in managing the flow of bulk materials from silos and bins, ensuring a streamlined and controlled release. With various designs and technologies available, making an informed choice requires a thorough understanding of your specific needs and the features of available products. This guide will explore critical aspects such as dust-tight sealing technologies and maintenance best practices to help you make an informed decision.

Dust-Tight Sealing Technologies: Why They Matter in Industrial Flow Control

Dust-tight sealing technologies are crucial for maintaining the integrity and safety of the material handling process. In industries such as agriculture, mining, and chemicals, where bulk materials are prevalent, preventing dust emissions is a significant concern. Dust not only poses health risks to workers but can also lead to equipment malfunction and increased maintenance costs.

The Importance of Dust Control

- Health and Safety: Dust particles can pose serious health risks, causing respiratory issues and other health problems for workers. Implementing effective dust-tight sealing technologies can minimize these risks.

- Environmental Compliance: Many industries are subject to strict environmental regulations regarding dust emissions. Compliance with these regulations is essential to avoid fines and maintain operational licenses.

- Equipment Longevity: Dust can lead to wear and tear on equipment, reducing its lifespan. A dust-tight seal helps protect machinery, ensuring longer service life and reducing maintenance costs.

Advanced sealing technologies, such as inflatable seals and precision-machined gate seats, offer superior dust control by providing an airtight barrier that prevents leakage. These technologies are essential for maintaining a clean and safe working environment.

Maintenance Best Practices for Flow Control Gates in Silo and Bin Outlets

Regular maintenance of flow control gates is essential to ensure their optimal performance and longevity. Proper maintenance not only enhances operational efficiency but also prevents unexpected downtimes and costly repairs.

Key Maintenance Practices

- Routine Inspections: Conduct regular inspections to check for signs of wear and tear, such as cracks or corrosion. Early detection of issues allows for timely repairs and prevents further damage.

- Lubrication: Ensure that all moving parts are adequately lubricated, reducing friction and wear. Regular lubrication helps maintain smooth operation and extends the life of the gate.

- Cleaning: Regularly clean the gates to remove any material build-up that could affect their functionality. Accumulated material can lead to blockages and operational inefficiencies.

By adhering to these maintenance practices, industries can ensure that their flow control gates continue to function effectively, minimizing downtime and maximizing productivity.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Routine Inspections | Monthly | High |

| Lubrication | Bi-Monthly | Medium |

| Cleaning | Weekly | High |

FAQs

What are flow control gates used for?

Flow control gates are used to regulate the flow of bulk materials from silos and bins. They help ensure a controlled and efficient release of materials, which is crucial for maintaining operational efficiency in industrial processes.

Why is dust-tight sealing important?

Dust-tight sealing is important because it prevents dust emissions, which can pose health risks to workers and lead to equipment malfunction. It also ensures compliance with environmental regulations and helps maintain a clean working environment.

How often should flow control gates be inspected?

Flow control gates should be inspected regularly, ideally on a monthly basis, to identify any signs of wear and tear. Regular inspections help in early detection of issues, allowing for timely maintenance and repairs.

What are the benefits of using advanced sealing technologies?

Advanced sealing technologies, such as inflatable seals, provide superior dust control by creating an airtight barrier. This prevents leakage, enhances environmental compliance, and extends the lifespan of equipment by reducing wear and tear.

How can regular maintenance extend the life of flow control gates?

Regular maintenance, including inspections, lubrication, and cleaning, helps prevent wear and tear, reduces operational inefficiencies, and minimizes the likelihood of unexpected downtimes, thereby extending the life of flow control gates.

Conclusion

Choosing the right flow control gate is essential for efficient bulk material handling. By understanding the importance of dust-tight sealing technologies and implementing best maintenance practices, industries can enhance their operational efficiency, ensure safety, and extend the lifespan of their equipment. Whether you are looking for advanced sealing solutions or seeking to improve maintenance protocols, companies like flowcontrolgate offer a range of products and services designed to meet the diverse needs of industrial operations.