Maintenance Made Easy: Smart Design Features of Modern Flow Control Gates

Today’s gates use modular bodies, standardized wear liners, and quick-release seals so technicians can inspect, clean, or swap components without disassembling upstream equipment. Smooth internal geometries reduce hang-ups and prevent material packing, minimizing the need for intrusive interventions. Accessible inspection ports placed at ergonomic heights shorten the time for daily checks. Combined with simple visual indicators for blade position and seal condition, these features let small teams maintain large systems with consistent, repeatable outcomes.

Smart maintenance is enabled by details like tool-less latches, cam-lock wear plates, and dovetail slide rails that allow gate blades or liners to be changed in minutes. Self-cleaning scraper edges prevent fines from accumulating along travel paths, cutting friction and reducing actuator strain. Sealed-for-life bearings and corrosion-resistant fasteners hold their tolerance in harsh washdown or dusty environments. Plants adopting these design elements typically report 25–40% reductions in maintenance time on gating assemblies, along with fewer nuisance stoppages and safer interventions at shift changeovers (Source, 2025).

Embedded sensors—position encoders, vibration nodes, and cycle counters—turn the gate into a service-aware asset. Instead of calendar-based overhauls, crews can trigger condition-based work orders when seal wear crosses thresholds or cycle counts approach service intervals. This predictive approach raises mean time between failures and reduces surprise downtime windows by double-digit percentages (Source, 2025). Because the flow control gate provides consistent behavior across its stroke thanks to tighter tolerances, recalibration events are less frequent, and technicians can verify performance quickly with built-in test routines, supporting reliability-centered maintenance practices across the line.

Key maintenance enablers in daily operation

Tool-less inspection and quick-change wear parts

Smart latching and keyed components make inspections efficient and precise. Technicians can remove guard plates and view the blade edge, seals, and liner wear patterns without disturbing upstream hoppers. Quick-change liners slide into position with fixed stops, ensuring correct geometry every time and eliminating guesswork that can cause inconsistent flow. Color-coded seals and etched wear indicators speed up decisions about replacements. With fewer loose fasteners and no custom jigs, parts swaps move from a half-day task to a scheduled 20–30 minute window, and the gate returns to service delivering repeatable flow profiles without extended re-tuning (Source, 2025).

Dust-tight and hygienic design for cleanability

Maintenance is faster when cleanup is minimal. Labyrinth edges, compressed gaskets, and continuous welds create a dust-tight envelope, reducing fugitive dust that otherwise drives housekeeping and bearings wear. For food and pharma, smooth, crevice-free surfaces and FDA-compliant liners support dry cleaning or foam-and-rinse routines without harboring residues. Plants report smaller cleanup crews and faster sanitation cycles when switching recipes, plus up to 40% less airborne particulate near transfer points when using modern sealing geometries and integrated extraction ports at the gate throat (Source, 2025). The result is cleaner audits, longer component life, and less time spent chasing contamination risks.

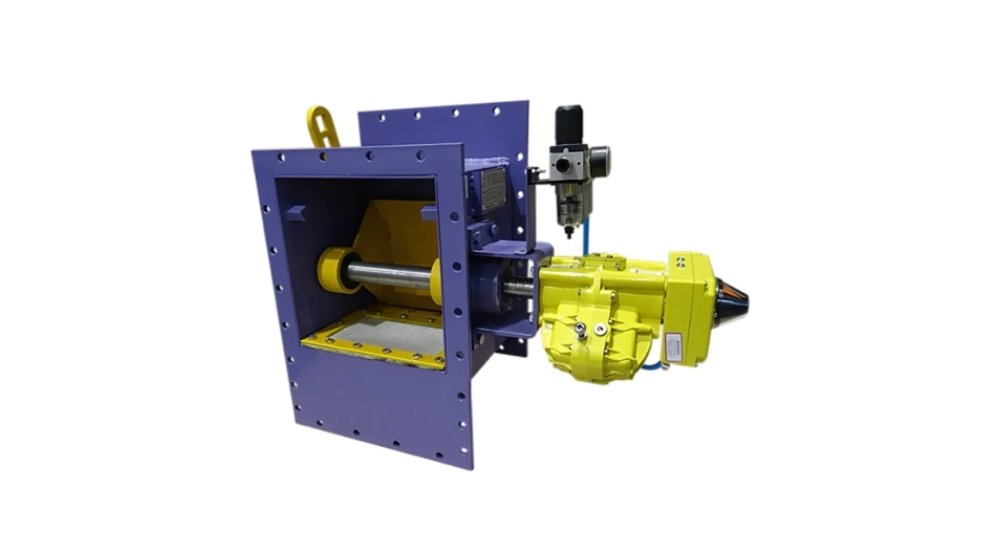

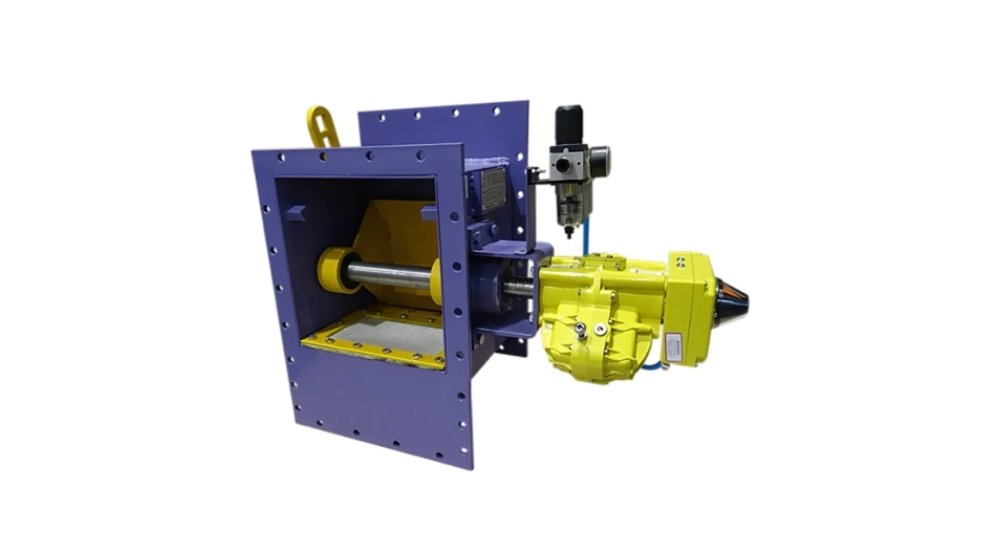

Flow Control Gate: High-Precision Solutions for Bulk Material Handling

Achieving consistent and repeatable results in dosing, blending, or loading hinges on the precision of the flow control gate. Unlike simple on/off slides, precision gates deliver stable, linear flow across the stroke, balancing friction, blade geometry, and throat profile to maintain mass flow over wide ranges. Whether handling powders, pellets, or granules, the controllability of the restriction point minimizes startup surges and end-of-batch dribble. This translates into tighter batch tolerances, cleaner cutoffs at target weights, and fewer corrections downstream—key wins for quality and throughput in systems where every second and every gram count.

Modern gates pair servo or proportional pneumatic actuation with high-resolution position feedback and closed-loop control. Integrated with load cells or flow meters, they adjust in milliseconds to disturbances like density changes or fluctuating head pressure, preserving setpoints with remarkable fidelity. Well-tuned systems regularly reach ±1–2% repeatability on mass flow and sub-second response to setpoint changes, even with cohesive powders prone to arching (Source, 2025). The net effect is process stability: fewer alarms, reduced rework, and smoother operation at higher speeds without sacrificing accuracy—especially valuable in multi-line facilities chasing OEE gains.

Seamless integration into PLC/SCADA unlocks recipe-based profiles—custom opening curves, ramp rates, and soft closes that prevent segregation or sifting. Digital calibration tools characterize each gate’s stroke to linearize output, while diagnostics log cycle counts and torque peaks for proactive service. With standardized I/O and industrial protocols, plants can drop a new gate into legacy lines and still gain data-rich control. Providers like flowcontrolgate package these capabilities in compact footprints, so upgrades fit tight transfer points. When batch accuracy and consistency are audited, these gates provide the traceable, repeatable records that quality teams rely on (Source, 2025).

| KPI / Metric | Manual Slide Gate | Pneumatic Gate (On/Off) | Smart Servo Flow Control Gate |

|---|---|---|---|

| Flow Accuracy (steady-state) | ±10–20% | ±5–10% | ±1–3% |

| Repeatability Batch-to-Batch | Variable; operator-dependent | Moderate; pressure-dependent | High; closed-loop verified |

| Response Time to Setpoint Change | >1 s | 300–600 ms | 50–150 ms |

| Planned Maintenance Downtime/Quarter | 6–8 hours | 4–6 hours | 1–2 hours |

| Dust Emissions at Gate | High | Medium | Low with capture |

Calibration and control strategies that drive accuracy

Multi-position profiling and servo tuning

Precision starts with a characterized stroke. During commissioning, teams map flow versus position to generate a gate-specific curve, then apply linearization inside the PLC or drive. Servo tuning addresses deadband and overshoot so the blade lands exactly on target without hunting. For materials with shifting bulk density, recipe-based profiles refine the opening at start, mid, and end-of-batch to maintain mass flow uniformity. The result is predictable performance: consistent cutoffs, stable feed rates, and smoother transitions when operators switch SKUs or container sizes without reworking downstream feeders or scales (Source, 2025).

Feedback sensors and adaptive algorithms

Closed-loop control is amplified with real-time feedback from load cells, impact flow meters, or optical mass flow sensors. The PLC blends position data with measured flow and applies adaptive PID or gain scheduling to keep the process on target, even as head height or moisture shifts. Advanced sites leverage model-based controls to anticipate disturbances and act preemptively. Diagnostics flag rising actuator torque or cycle times as early indicators of seal wear, so teams fix drift before it affects product quality. The combination delivers consistent, repeatable results across long runs and seasonal material variation.

Frequently Asked Questions

What materials are best suited for a flow control gate?

A flow control gate performs well with powders, granules, and pellets, including cement, fly ash, sugar, plastic resin, and grains. Selection of blade style, liner material, and throat geometry tailors the gate to abrasiveness, particle size, and cohesiveness. With the right sealing package and anti-stick liners, even fine, aeratable powders can be metered consistently without bridging or rat-holing, supporting reliable batching and dosing across product families.

How do I size a flow control gate for my line?

Sizing starts with target mass flow, material bulk density, and the available head pressure above the restriction. Engineers model flow versus opening and choose a gate size that delivers the required rate in the middle of the stroke, preserving control authority for upsets. Accounting for wear allowances, dust extraction clearances, and actuator speed ensures the chosen gate achieves setpoints quickly while retaining repeatability, especially during cutoffs near the end of batch.

Can a flow control gate eliminate material segregation?

While no device fully eliminates segregation, a properly tuned flow control gate reduces the conditions that cause it. Soft-start ramps and controlled closing rates minimize velocity spikes and impact that separate fines from coarse fractions. Pairing the gate with mass-flow hoppers and short drop heights further limits sifting, improving blend uniformity and batch consistency without compromising the required throughput or target weight accuracy (Source, 2025).

What maintenance schedule should I follow for consistent results?

Use condition-based maintenance guided by cycle counts, position trends, and actuator torque rather than a fixed calendar. Check seals, liners, and scraper edges during scheduled inspections, and replace when wear indicators reach thresholds for your material class. Keep spares on hand and validate performance with a quick calibration test after service to ensure the gate’s flow-versus-position curve remains stable and repeatable across runs.

How does a flow control gate compare to a rotary valve for metering?

A rotary valve can provide volumetric feeding, but its slip and wear introduce drift that complicates tight batch targets as conditions change. A flow control gate, especially in closed-loop with mass feedback, directly regulates material discharge area for a more linear and adaptable response. Plants often use gates for precise cutoffs and dynamic control, while reserving rotary valves for isolation or gentle transfer where high accuracy is not the priority (Source, 2025).

Follow Us

For more insights on precision flow control, reliability tips, and case studies, follow us on our official channels. Stay updated with new application notes, maintenance checklists, and performance benchmarks to help your team boost accuracy and uptime across every line.