Flow Control Gate

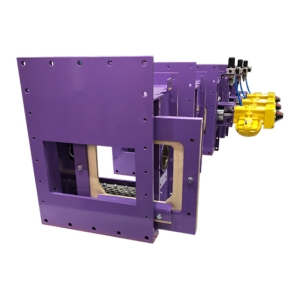

In industrial material handling and process automation, regulating the flow of materials with precision is essential. This is where the Flow Control Gate plays a critical role. Designed to act as a proportional valve, the Flow Control Gate enables highly accurate and reliable control of bulk materials in a wide range of applications. Whether used in cement plants, chemical industries, food processing, or mining operations, Flow Control Gates offer unmatched consistency, durability, and precision.

What is a Flow Control Gate?

A Flow Control Gate is a specially designed mechanical device used to regulate the flow rate of granular or powdered materials through a pipeline or chute. It is not just a simple on-off valve; rather, it allows proportional control, adjusting the flow between 0% and 100% based on the process requirements.

A Flow Control Gate is a specially designed mechanical device used to regulate the flow rate of granular or powdered materials through a pipeline or chute. It is not just a simple on-off valve; rather, it allows proportional control, adjusting the flow between 0% and 100% based on the process requirements.

These gates are typically installed in material transport lines, silos, hoppers, or conveyors where accurate metering of flow is crucial. By adjusting the gate’s position, operators can finely tune the flow rate depending on the system’s demand, ensuring smooth and efficient operation.

Drive Types and Control Mechanism

- Pneumatic actuators

- Geared motors

The pneumatic drive option is preferred in environments where quick and precise control is needed. In this case, Kinetrol UK actuators and positioners are commonly used due to their high performance, durability, and precision. Notably, Mor Endüstri Ltd., based in Turkey, is an official distributor of Kinetrol products and integrates these world-class actuators into their flow control systems.

For facilities requiring electric control, geared motor-driven gates are also available. These are ideal for slower operations where electric power is preferred over compressed air systems.

Positioning and Control Feedback

Flow Control Gates provide positioning from 0° to 90°, which translates to full control over the degree of gate opening. The system is equipped with a feedback loop using a 4-20mA signal, enabling real-time position control. This linear control aperture allows smooth adjustment of material flow without causing sudden changes or turbulence in the process.

Dust-Tight Shut-Off and Sealing

Industrial processes involving powdered or granular materials often face challenges like dust leakage, which can lead to environmental and safety hazards. To address this, Flow Control Gates are designed with dust-tight sealing mechanisms.

The gates feature an exchangeable cassette-type seal, ensuring minimal downtime and easy maintenance. This smart design reduces operating costs while extending the equipment’s lifecycle.

Durable Construction

The body and roller of the Flow Control Gate are constructed using steel, offering high mechanical strength and resistance to wear. This robust design makes the gate suitable for heavy-duty and continuous operations in demanding industrial environments.

Additionally, the gate includes a manual adjustment lever, which allows operators to override automatic control in case of emergencies or maintenance.

Fail-Safe Operation

Safety is paramount in industrial settings. The Flow Control Gate is engineered to remain “Normally Closed” in the event of power loss or air supply failure. This fail-safe mechanism prevents uncontrolled material discharge, helping avoid equipment damage or safety incidents.

Why Choose Mor Endüstri Ltd.?

Mor Endüstri Ltd. has earned a solid reputation for manufacturing high-quality Flow Control Gates. By combining its long-standing experience in gate production with the precision of Kinetrol actuators, the company delivers systems that are:

- Highly accurate

- Easy to maintain

- Long-lasting

- Customizable according to drive type, size, and application

From pneumatic cylinder-driven to geared motor-driven models, Mor Endüstri tailors each product to the client’s operational requirements. Their partnership with Kinetrol UK also ensures the incorporation of cutting-edge actuator technology into every gate they produce.

Frequently Asked Questions (FAQ)

- 1. What is the main function of a Flow Control Gate?

- A Flow Control Gate regulates the flow rate of bulk materials through a system. Unlike simple on/off gates, it provides proportional control, allowing for fine adjustment of material flow.

- 2. What types of actuators are available?

- The gate can be driven by pneumatic actuators or geared motors, depending on the control system and process needs.

- 3. Why is Kinetrol preferred for pneumatic drives?

- Kinetrol actuators are renowned for their precision, reliability, and long service life. Mor Endüstri Ltd. uses Kinetrol products in its pneumatic-driven gates for their superior quality and control capabilities.

- 4. Is the Flow Control Gate safe during a power failure?

- Yes. The gate is designed to remain in a “Normally Closed” position in case of power or air failure, ensuring safe operation.

- 5. Can the gate be adjusted manually?

- Absolutely. A manual lever is provided for manual control and adjustments when needed.

- 6. How is maintenance handled?

- The cassette-type sealing system allows for quick replacement and easy maintenance, reducing downtime and operational costs.

- 7. What materials are used in its construction?

- The housing and rollers are made of high-quality steel, ensuring durability and strength under heavy loads.

- 8. What is the positioning range?

- The gate can be positioned anywhere between 0° and 90°, with position feedback via a 4-20mA signal for accurate control.

Conclusion

The Flow Control Gate is a critical component in material handling systems that require precision, safety, and reliability. With advanced features like proportional control, fail-safe design, and easy maintenance, these gates significantly enhance operational efficiency. Companies like Mor Endüstri Ltd., with their expertise and partnership with Kinetrol UK, ensure that you get the best in technology and craftsmanship. Whether you’re upgrading your plant or installing a new system, choosing the right Flow Control Gate can make all the difference in performance and safety.